As you practice for your mechanical aptitude test, you might come across challenging topics like pulleys and gears. This study guide will help you build a solid understanding of these concepts and approach the test with greater confidence.

For comprehensive mechanical preparation resources, see the following:

Gears in Mechanical Tests

Pulleys questions are very common in mechanical aptitude tests. A basic knowledge of this topic makes them very easy to solve: therefore, by becoming familiar with pulleys, you are guaranteed to score high on your test.

What are Pulleys, Precisely?

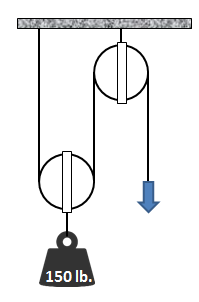

A pulley is a simple machine combined of a wheel on an axle and a rope wrapped around it. With a rope and an effort, the pulley can be used for lifting loads. A fixed pulley alters the direction of the applied force: for example, when a man will pull the rope downwards, the load will be elevated. A movable pulley provides a mechanical advantage in lifting, and thus a load would require half the effort in order to be lifted. A combination of both will allow the mechanical advantage along with the directional advantage.

In mechanical aptitude tests, pulleys are considered one-dimentional; therefore, their size and the friction created among their parts are omitted.

Common Pulleys Questions

Usually, you will be required to determine the amount of force required to lift a load.

For example:

What would be the direction and amount of force required to lift the following load?

Typically, most pulley questions may be more complicated than the sample above, and may contain more components or confusing connections. Our practice packs contain a large variety of pulley questions at all levels, so that every aspect of pulleys will become comprehensible to you and grant you the confidence you need in order to take a mechanical aptitude test.

Gears in Mechanical Tests

The topic of gears is very prevalent in mechanical aptitude tests. Without proper preparation, this topic may seem confusing; however, with our Mechanical PrepPacks, you can easily gain all the knowledge required for your test.

What are Gears, Precisely?

A gear, or a cogwheel, is a wheel on which circumference there are equally sized and spaced teeth. The cogwheel is designed to transfer the circular torque (i.e. the circular movement of force) to an additional cogwheel.

When one cogwheel is turning in a certain direction, the other cogwheel meshed with it will turn in the opposite direction.

Common Gears Questions

Usually, you will be required to distinguish the direction and / or velocity of the portrayed cogwheels.

For example: In the following illustration, cogwheel 1 is turning in a counterclockwise direction.

In which direction would cogwheel 3 turn?

This question’s level is easy, and more difficult questions may include a complex system with a larger number of wheels. Also, in some questions, cogwheels may be meshed with different toothed components, such as internal cogwheels or rack and pinion; in others, you may be required to calculate velocities. Our study guide can provide you with all the tools you need in order to solve these questions.

Prepare - Practice More Pulley and Gear Questions

In order to provide yourself with the best conditions to do well on your test, you must do the basic learning required and solve practice questions. The more questions you are exposed to, the better you are likely to do on your test. JobTestPrep offer an extensive Mechanical Practice Packs, which include everything you need: practice tests developed exclusively for your test, solutions and explanations, study guides, tips, and advice.